Lock nuts are supplied as standard on both ends of terminal. Jaw terminals are supplied with bolt & Nut with cotter pin. Turn Buckles are recommended for straight or in-line pulls only. Body with “TL” marking will be supplied. Proof Load is 2 times of working load limit and minimum breaking load 5 times of working load limit. All Toyolift Turn buckles are drop forged, heat treated and hot dipped galvanized.

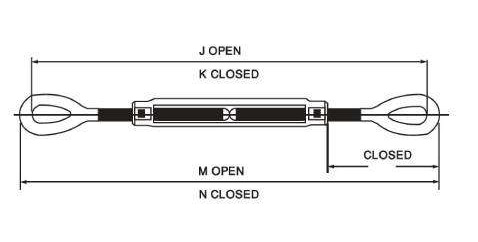

Eye & Eye Turnbuckles - Hot Dip Galvanised

| Thread Diameter & take up (in.) | Dimensions | |||

|---|---|---|---|---|

| J | K | M | N | |

| Open | Closed | Open | Closed | |

| 1/4 x 4 | 300 | 198 | 311 | 210 |

| 5/16 x 4-1/2 | 344 | 230 | 359 | 244 |

| 3/8 x 6 | 444 | 291 | 461 | 309 |

| 1/2 x 6 | 510 | 332 | 532 | 355 |

| 1/2 x 12 | 815 | 485 | 837 | 507 |

| 5/8 x 6 | 557 | 373 | 582 | 398 |

| 5/8 x 12 | 862 | 525 | 887 | 551 |

| 3/4 x 6 | 607 | 416 | 638 | 448 |

| 3/4 x 12 | 911 | 568 | 943 | 600 |

| 3/4 x 18 | 1216 | 721 | 1248 | 752 |

| 7/8 x 12 | 942 | 592 | 980 | 630 |

| 7/8 x 18 | 1246 | 745 | 1284 | 783 |

| 1 x 6 | 710 | 507 | 755 | 552 |

| 1 x 12 | 1015 | 660 | 1066 | 704 |

| 1 x 18 | 1320 | 812 | 1364 | 856 |

| 1 x 24 | 1625 | 964 | 1669 | 1009 |

| 1-1/4 x 12 | 1087 | 719 | 1145 | 776 |

| 1-1/4 x 18 | 1392 | 871 | 1449 | 929 |

| 1-1/4 x 24 | 1697 | 1024 | 1754 | 1081 |

| 1-1/2 x 12 | 1156 | 775 | 1219 | 838 |

| 1-1/2 x 18 | 1461 | 927 | 1524 | 991 |

| 1-1/2 x 24 | 1765 | 1080 | 1829 | 1143 |

| 1-3/4 x 18 | 1457 | 1000 | 1534 | 1076 |

| 1-3/4 x 24 | 1762 | 1153 | 1838 | 1229 |

| 2 x 24 | 1923 | 1313 | 2011 | 1402 |

| 2-1/2 x 24 | 1997 | 1387 | 2099 | 1489 |

| 2-3/4 x 24 | 2057 | 1448 | 2172 | 1562 |

Lock nuts are supplied as standard on both ends of terminal. Jaw terminals are supplied with bolt & Nut with cotter pin. Turn Buckles are recommended for straight or in-line pulls only. Body with “TL” marking will be supplied. Proof Load is 2 times of working load limit and minimum breaking load 5 times of working load limit. All Toyolift Turn buckles are drop forged, heat treated and hot dipped galvanized.

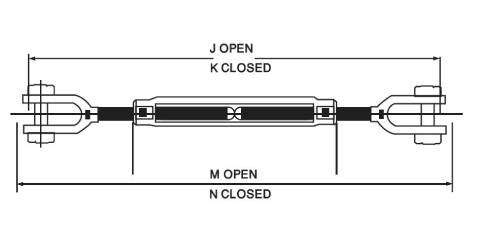

Jaw & Jaw Turnbuckles -Hot Dip Galvanised

| Thread Diameter & take up | Dimensions | |||

|---|---|---|---|---|

| J | K | M | N | |

| (in.) | Open | Closed | Open | Closed |

| 1/4 x 4 | 277 | 175 | 302 | 201 |

| 5/16 x 4-1/2 | 314 | 212 | 353 | 239 |

| 3/8 x 6 | 410 | 258 | 441 | 289 |

| 1/2 x 6 | 470 | 292 | 508 | 330 |

| 1/2 x 9 | 622 | 368 | 660 | 406 |

| 1/2 x 12 | 775 | 445 | 813 | 483 |

| 5/8 x 6 | 509 | 325 | 562 | 378 |

| 5/8 x 9 | 662 | 401 | 715 | 454 |

| 5/8 x 12 | 814 | 478 | 867 | 530 |

| 3/4 x 6 | 546 | 356 | 612 | 422 |

| 3/4 x 9 | 699 | 432 | 765 | 498 |

| 3/4 x 12 | 851 | 508 | 917 | 574 |

| 3/4 x 18 | 1156 | 660 | 1222 | 726 |

| 7/8 x 12 | 892 | 543 | 967 | 618 |

| 7/8 x 18 | 1197 | 695 | 1272 | 770 |

| 1 x 6 | 628 | 425 | 713 | 510 |

| 1 x 12 | 933 | 577 | 1018 | 662 |

| 1 x 18 | 1237 | 729 | 1322 | 814 |

| 1 x 24 | 1542 | 882 | 1627 | 967 |

| 1-1/4 x 12 | 1012 | 644 | 1119 | 750 |

| 1-1/4 x 18 | 1317 | 796 | 1423 | 903 |

| 1-1/4 x 24 | 1622 | 948 | 1728 | 1055 |

| 1-1/2 x 12 | 1054 | 673 | 1181 | 800 |

| 1-1/2 x 18 | 1359 | 826 | 1486 | 953 |

| 1-1/2 x 24 | 1664 | 978 | 1791 | 1105 |

| 1-3/4 x 18 | 1356 | 899 | 1503 | 1046 |

| 1-3/4 x 24 | 1661 | 1051 | 1808 | 1198 |

| 2 x 24 | 1766 | 1157 | 1949 | 1339 |

| 2-1/2 x 24 | 1854 | 1244 | 2087 | 1478 |

| 2-3/4 x 24 | 1899 | 1289 | 2172 | 1562 |